Space

Once in orbit, it is very quiet for most satellite modules. Inevitable when there is no air or gas around. And vibration wise, slight orbit corrections are probably the most ‘exciting’ events. So noise and vibration does not seem to be a major concern. But, there is a slight worry; during launch the opposite is true. Extreme levels of vibration forces and pressure waves are released by the launch vehicle and risk damaging the modules/experiments, solar collector, etc.. And to test this, space bound modules, experiments, satellites are exposed to +- 145 dB sound pressure roughly during a few minutes.

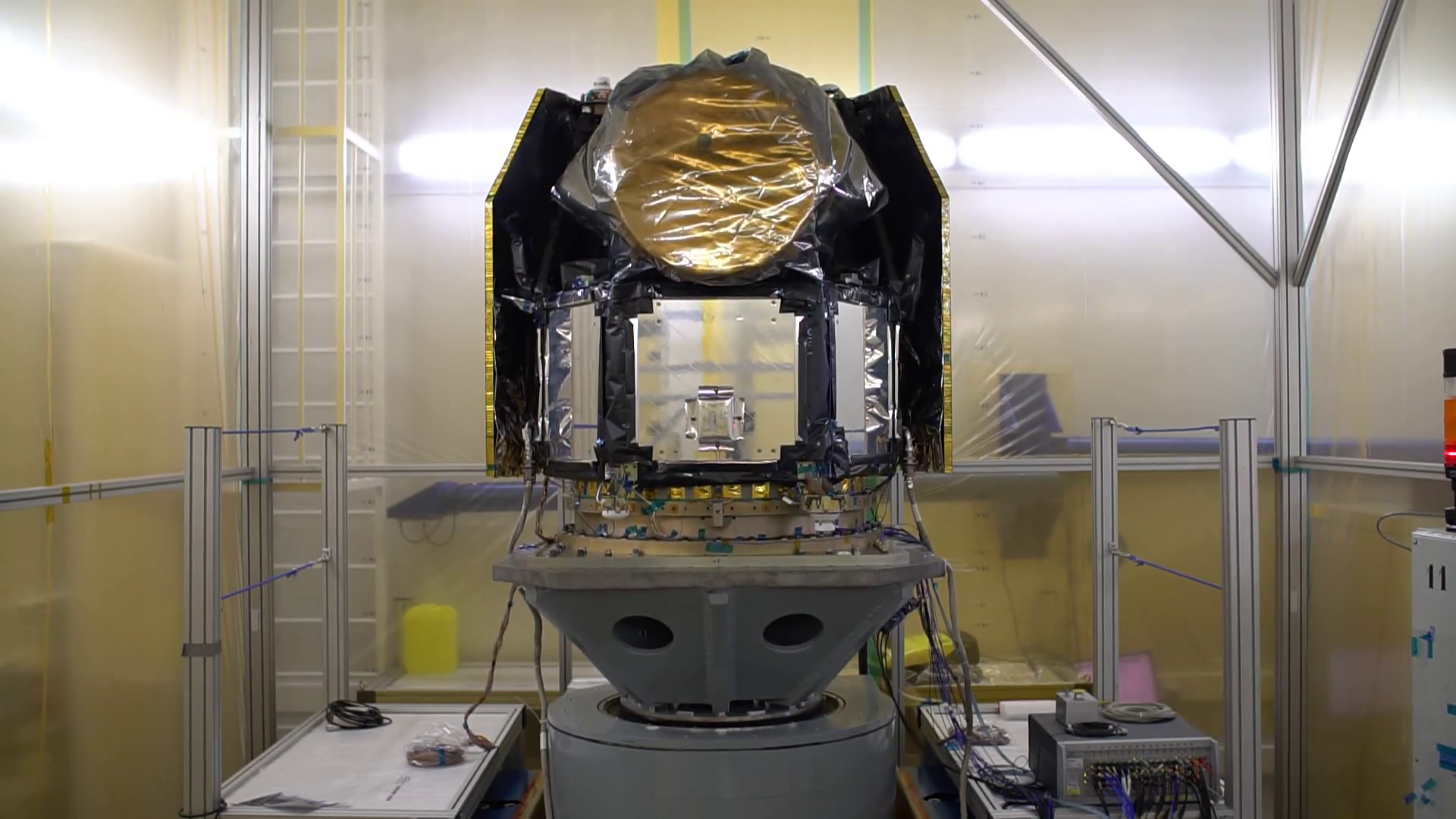

Control is essential. The qualification tests intend to prevent failures in mission. Preparation for these qualifications begins much earlier. Before hardware reaches a qualification facility, engineers conduct virtual vibration simulations—including sine, random, and coupled-load analyses—using detailed finite element (FE) models. These simulations require experimentally validated structural dynamics to produce reliable predictions.

FE models of primary and secondary satellite structures, composite panels, payload platforms, and avionics units must accurately reflect stiffness distributions, mode shapes, damping behavior, and boundary conditions. Lightweight construction methods and complex joint interfaces often introduce uncertainties that simulation alone cannot resolve.

To ensure predictive fidelity, Experimental Modal Analysis (EMA) is applied to capture high-quality modal parameters directly from hardware. These measurements form the foundation for FE correlation and subsequent model updating.

On some modules, like life-sustaining systems for a manned space station, the vibration generation and noise emission is highly relevant. And in those case the same techniques and same Qssources excitation hardware as used in automotive and railway can be applied like transfer path analysis, interface load identification, FRF based sub structuring are available to analyse and optimize.

Precision is needed. Qsources excitation technology is designed specifically for the modal characterization and model validation phase preceding qualification testing.

The systems deliver stable broadband force input with integrated force measurement, allowing acquisition of clean and reliable frequency response functions (FRFs). Their compact, self-supporting configuration minimizes mass loading and enables efficient deployment in clean-room or laboratory environments commonly used for spacecraft assemblies.

Some Applications

Panel vibro-acoustic modal analysis

Payload Fairing (PLF) helps reduce exposure of critical components or experiments from the extreme sound pressure during launch. But these panels, as well as deployable solar collectors, radiation protecting panels and other light-thin elements are themselves the most vulnerable to the dynamic pressure loads during launch. So there is great benefit in correct understanding and modelling on these elements.

Measuring the modal parameters on those panels is a challenge because of the shifts in their vibration due to anything attached to the foils or panels, But deriving accurate modal data is still highly desirable to improve the FE models of such light components for analysis.

Optical sensing of responses can take away the mass loading and damping introduced by sensors. And acoustic excitation with a volume sound source can take away any mass or impedance loading by the excitation. And the Qsources volume sources provide a real time volume acceleration signal which allows to obtain scaled modal parameters, even on the structure part of the system under acoustic excitation. Suitable sound sources for such experiments in decreasing size and power level:

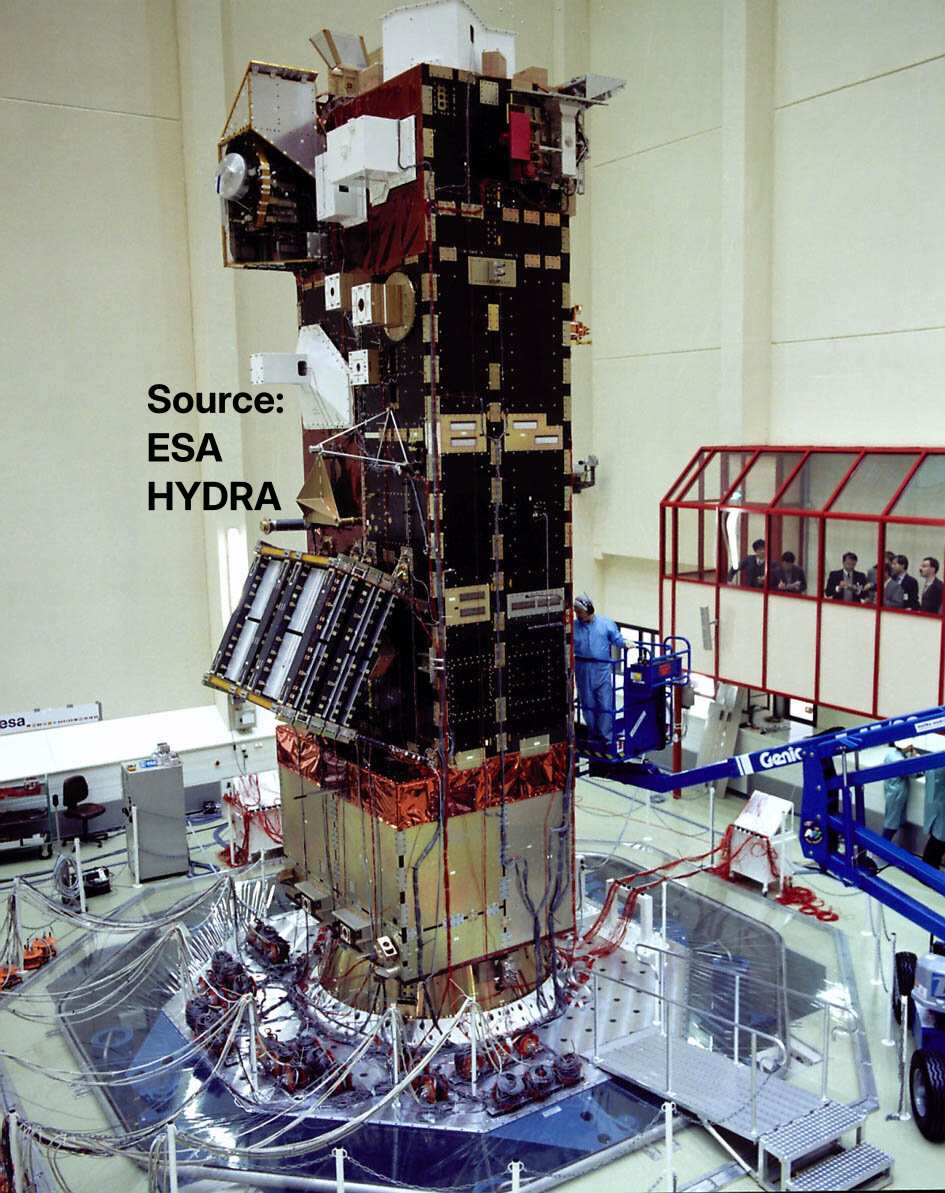

Carrier structure vibration analysis

From FE model development to experimental based correlation. Aerospace vibration engineering begins with the creation of detailed FE models. Once hardware becomes available, EMA using Qsources exciters provides the experimental dataset needed for comparison with predicted modal characteristics. Discrepancies identified during correlation are resolved through FE model updating, thereby improving agreement between simulated and measured responses.

Supporting virtual vibration testing. Validated FE models enable more reliable virtual analyses, including random and sine vibration response, notching strategy definition, interface load estimation, and coupled-load dynamic simulations. Improved model fidelity reduces uncertainty and increases confidence in pre-qualification predictions.

Preparing for qualification-level testing. A well-correlated FE model supports accurate qualification planning and reduces unexpected behavior during full-scale shaker campaigns. High-quality modal data therefore plays a critical role in ensuring efficient, predictable, and compliant qualification testing.

Precision structural excitation for the modal testing is needed. The structural excitation devices from Qsources offer some specific advantages relative to alternative means of structure excitation.

Broadband excitation with situation-adaptable signals

Stable and repeatable output force

Well defined and extremely low mass loading

Well defined system for adhesive attachment of the shakers

Highly compact requiring minimal space and a minimal footprint

Any inclination is possible and equally accurate

Integrated force sensor (and integrated in-line acceleration on some)

These various properties allow efficient and well controlled, repeatable deployment in any site. To measure on objects, from the smallest at 0.5 kg total weight up to the largest structures at 100.000 kg the following shakers are suitable:

Strengthening the Structural Verification Chain

The Qsources shakers and meausrement sound sources are not intended for the qualification itself, according to the current standard tests. They are intended for investigations, diagnosis, and simulation model improvement activities. Validated FE models are essential for simulation-driven spacecraft development. By enabling high-quality modal testing, Qsources excitation systems strengthen the structural verification chain—supporting accurate virtual vibration simulations and contributing to predictable and successful qualification campaigns.

All described measurements also require software and sensors, of which several are available in the market. Depending on the exact application our partners,

Head Acoustics, Siemens, Polytec,

all propose leading full chain solution including the Qsources excitation sources and shakers